Reducing Bat Mortality at Wind Farms with the Turbine Integrated Mortality Reduction (TIMR) Smart Curtailment Technology

Smart curtailment technology reduces bat mortality by shutting down turbines when bats are present and wind speeds are moderate

Summary of TIMR study

Smart curtailment uses bat presence with environmental variables to inform wind turbine shut down with the goal of reducing or preventing bat fatalities. This approach is beneficial over blanket curtailment— where the turbine shutdown is based on wind speed only—because bat mortality can be reduced with less impact to the economics of the wind farm. We tested the Turbine Integrated Mortality Reduction (TIMR) system—a smart curtailment system designed to reduce bat mortality with minimal effects on economic output—against normal turbine operation. Compared to turbines that were operating normally, turbines controlled by TIMR saw mortality reductions ranging from 74.2% to 91.4%, depending on the species (Table 1). The advantage of smart curtailment over traditional blanket curtailment are large reductions in bat fatalities with less of an impact on power generation compared to blanket curtailment or normal operation.

| Common Name | Scientific Name | % Mortality Reduction with TIMR Smart Curtailment |

|---|---|---|

| Little brown bat | Myotis lucifugus | −91.4 |

| Big brown bat | Eptesicus fuscus | −74.2 |

| Silver-haired bat | Lasionycteris noctivagans | −90.9 |

| Hoary bat | Lasiurus cinereus | −81.4 |

| Eastern red bat | Lasiurus borealis | −82.5 |

| All species | N/A | −84.5 |

Background

Bat mortality at wind farms has been well-documented in North America and may have population-level impacts. Bat mortality is most frequently reported during the fall and mainly consists of tree bat species: eastern red bat, silver-haired bat, and hoary bat. Bats also tend to be more active during lower wind speeds, and this time is when mortality risk is the highest.

One approach to reducing bat mortality at wind farms is to curtail (stop) turbine blades from spinning when wind speeds are below a certain threshold (e.g., 7 meters/second). This technique reduces bat mortality and also reduces the energy generation of the wind farm. Unfortunately, this approach curtails turbines when no bats are present, leading to unnecessary power generation loss. A better approach is to curtail turbines only when bats are present and when wind speeds are within the curtailment zone, thus minimizing mortality while maximizing wind turbine operation time. Using bat presence as a deciding factor for curtailment along with other variables is called smart curtailment.

In collaboration with EPRI, the studies described here represent a test of the Turbine Integrated Mortality Reduction (TIMR) system at the Blue Sky Green Field Wind Farm in Wisconsin. This controlled study measured the effectiveness of the TIMR system by comparing mortality at turbines where TIMR was operating to turbines where TIMR was not operating (turbines were operating normally). A second smart curtailment validation study is being conducted at the MidAmerican Wind Energy Center in Adair County, Iowa; at the time of this writing (March 2023), results from this study were not available.

The TIMR Smart Curtailment Technology

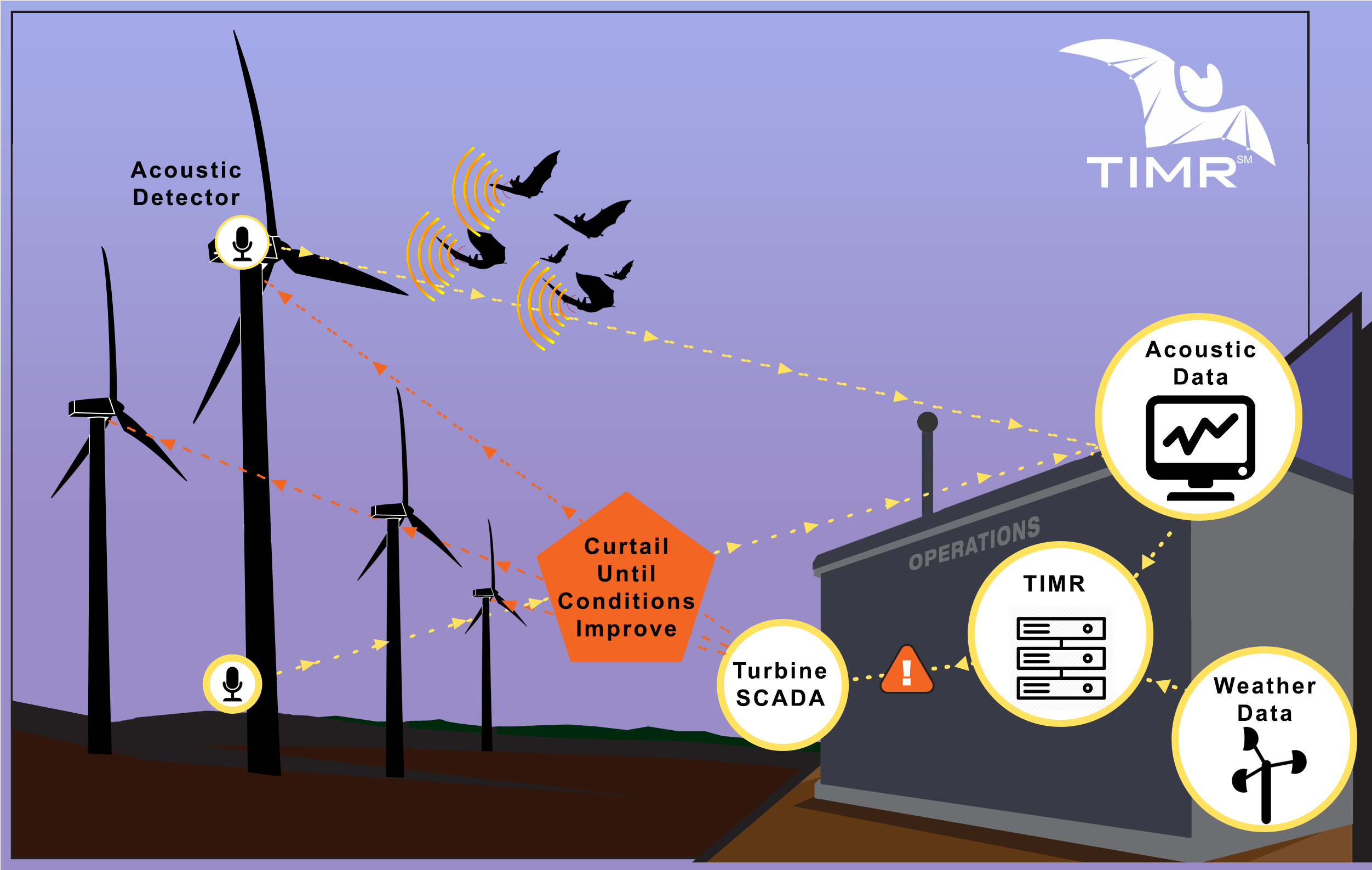

The TIMR system consists of three main components that provide a wind farm with smart curtailment:

- Bat acoustic detectors placed on the turbine nacelle to detect bats in the rotor-swept zone

- A TIMR server that processes bat acoustic data and wind speed data from the facility

- A SCADA interface to shut down the turbines if bats are present and winds are within the curtailment zone

All three of these components are custom configured for each wind farm based on results of a feasibility study of the wind regime and bat activity information garnered from acoustic monitoring or post-construction fatality data. While these data are not required to use a TIMR system, they are useful for better informing curtailment parameters before beginning a smart curtailment strategy. In addition, the TIMR system can meet a wind farm’s strict cybersecurity requirements regarding remote access of TIMR hardware. Great care is taken to work closely with wind facility staff to ensure that all security and logistical requirements are met.

Figure 1. Schematic of the TIMR system interacting with the bat detectors and wind farm SCADA.

TIMR Technology Testing

Blue Sky Green Field

The TIMR system was deployed at the Blue Sky Green Field wind farm from June 1, 2015, to October 31, 2015. Four bat detectors were deployed across the wind farm; at each turbine, they sampled the airspace above and below the nacelle. All audio files were subjected to an algorithm to detect probable bat calls. Bat detectors sent all probable call files to the TIMR server at the wind farm’s operations center, where acoustic data were processed in near real-time to inform turbine shutdown. Wind speed data were collected in 10-minute increments and provided by the SCADA system to the TIMR server. The average wind speed for each 10-minute period was used as the wind speed measurement when deciding on turbine shutdown.

The binary TIMR risk model uses 0 to indicate low risk (no curtailment) and 1 to indicate high risk (smart curtailment). High risk was determined if the measured wind speed was <8.0 m/s and ≥ 1 bat was detected in the previous 10 minutes: under these conditions, the turbines monitored by TIMR were curtailed; all control turbines operated normally. When high-risk conditions were identified, the turbines were curtailed for 30 minutes; after 30 minutes, the risk model reevaluated conditions every 10 minutes and would do so until low-risk conditions were identified. If the wind speed was ≥ 8.0 m/s, all turbines operated normally. Ten control and ten treatment turbines were searched once daily for bat fatalities during the June 1-October 31 study period. All plots were mowed and treated with herbicide to ensure carcasses were visible to observers.

For all species, the number of fatalities found at TIMR turbines (3-9 carcasses per species) were less than at control turbines (fully operational; 27–48 carcasses per species). After accounting for searcher efficiency and carcass persistence, the number of estimated fatalities was significantly higher at control turbines than at TIMR turbines; the distribution of Monte Carlo simulations did not overlap. Overall, this study estimates that TIMR decreased fatalities by 85% across all species and between 74-91% for individual species compared to control turbines. The annual reduction in power generation and revenue was 3.2% compared to control turbines. These results are similar to what was observed in other studies that examined the effect of blanket curtailment, but these didn’t use the presence of bats to inform the curtailment decisions. Note that these results presented here only apply to Blue Sky Green Field wind farm and to the specific configuration and curtailment parameters used. Using different cut-in speeds and/or curtailment thresholds could change the results significantly. Further research will indicate the extent to which adjusting TIMR configuration parameters will affect the fatality estimates.

MidAmerican Wind Farm

A TIMR validation study is being conducted at the MidAmerican Wind Energy Center in Adair County, Iowa, using a similar configuration to what was used at the Blue Sky Green Field Wind Facility. Unfortunately, results from this study are not publicly available at the time of writing (March 2023).

Further TIMR Research

Other ideas for extending and improving the TIMR technology and understanding other variables that may influence smart curtailment effectiveness include:

- Testing the optimal number of detectors for informing shutdown

- Understanding how detector-turbine proximity influences mortality

- Varying the wind speed range where curtailment occurs in relation to the wind regime at the site

- Constraining the acoustic filters so that curtailment only occurs when select species are detected

Other Smart Curtailment Systems

To my knowledge, two other smart curtailment systems are partially available:

- EcoPITCH—Developed by Stantec, this system allows the simulation of smart curtailment strategies based on bat activity, temperature, and wind speed. This approach uses existing data and models to inform curtailment strategies, rather than relying on real-time data collection and shutdown.

- EcoSense—Developed by Natural Power, this system is similar to TIMR and uses meteorological and bat activity data to inform turbine shutdown.

References

Arnett, E. B., M. M. Huso, M. R. Schirmacher, and J. P. Hayes. 2011. Altering turbine speed reduces bat mortality at wind energy facilities. Frontiers in Ecology and the Environment 9:209–214. https://esajournals.onlinelibrary.wiley.com/doi/10.1890/100103

Arnett, E. B., E. F. Baerwald, F. Mathews, L. Rodrigues, A. Rodriguez-Duran, J. Rydell, R. Villegas-Patraca, and C. C. Voigt. 2016. Impacts of wind energy development on bats: a global perspective. Pages 295–323 in C. C. Voigt and T. Kingston, editors. Bats in the Anthropocene: conservation of bats in a changing world. Springer International Publishing, New York, New York, USA. https://link.springer.com/chapter/10.1007/978-3-319-25220-9_11

Frick, W. F., E. F. Baerwald, J. F. Pollock, R. M. R. Barclay, J. A. Szymanski, T. J. Weller, A. L. Russell, S. C. Loeb, R. A. Medellin, and L. P. McGuire. 2017. Fatalities at wind turbines may threaten population viability of a migratory bat. Biological Conservation 209:172–177. https://www.sciencedirect.com/science/article/abs/pii/S0006320716310485?via%3Dihub

Hayes, M. A., L. A. Hooton, K. L. Gilland, C. Grandgent, R. L. Smith, S. R. Lindsay, J. D. Collins, S. M. Schumacher, P. A. Rabie, J. C. Gruver, and J. Goodrich-Mahoney. 2019. A smart curtailment approach for reducing bat fatalities and curtailment time at wind energy facilities. Ecological Applications 00(00):e01881:10.1002/eap.1881. https://esajournals.onlinelibrary.wiley.com/doi/abs/10.1002/eap.1881